Introduction

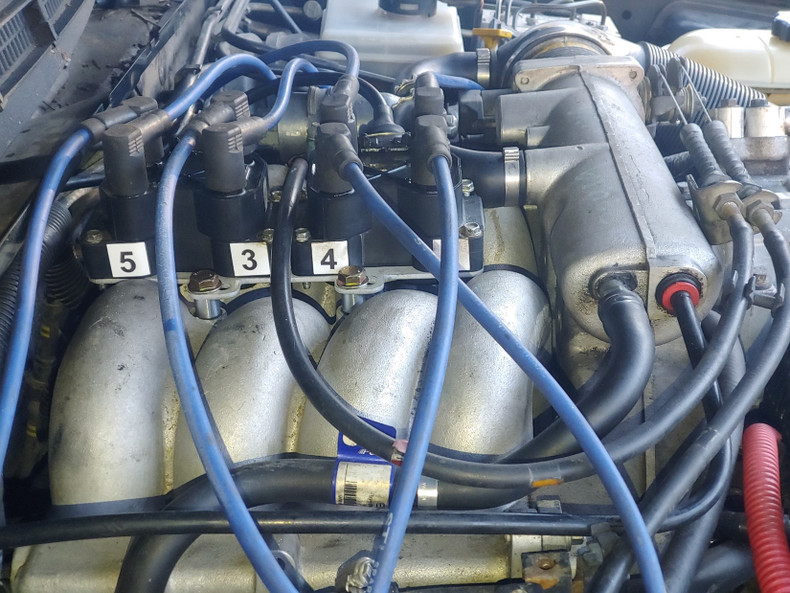

Anyone who has had to replace an ignition coil or spark plug wire on a Thor engined D2 or P38 understands how frustrating the factory coil pack location is.

Few modern vehicles have spark plug wires or coil packs as inaccessible as these, with a replacement requiring not just removal of the upper intake manifold for access, but removal of coil mounting bolts that you cannot see and can barely even feel to remove the upper intake.

Operational design

The ignition coil design of the D2 is quite interesting and could be called a "siamesed" design, as it is actually two ignition coils molding in one plastic assembly.

The Thor engine is not the only engine that uses this design, several Subaru and Hyundai engines use very similar siamesed coil designs.

So if this is two coils in one housing, why are there four spark plug wires attached? Well, the design uses what is called a "lost spark" style of ignition timing. When the ECU tells one of the siamesed coils to fire, it sends a spark down both plug wires to two cylinders. One is on the compression stroke and the other is on the exhaust stroke, the exhaust stroke spark does little to nothing hence it is "lost". Each molded housing has two of these coils, with separate trigger wires for firing the two coils.

Design Pros and Cons

On the positive side, this design is undoubtedly more economical either the D1 style 8 in one coil or the more common single coil per cylinder design.

Additionally it has the advantage of being relatively compact from an engine compartment packaging scenario. However, the nature of the design is such that when one of the siamesed coils fail, you lose two cylinders out of the firing order and not just one. Anyone who has experienced this knows the engine runs very rough and will barely move a 5000+ lb Land Rover on relatively level city streets, much less up a steep trail or mountain pass. On top of that the ECU begins flashing the CEL at you indicating catalytic converter damaging misfire. Sometimes, the coils begin to fail only under high load, when significant power is needed and cylinder pressure increases the voltage needed to fire. It can be possible to limp along with this situation for some time period and it is tempting do so given the size of the task to change a coil with the factory design. Unfortunately, more often than not whatever causes the initial half of the coil to fail usually results in the other half failing not long after, rendering your V8 down four cylinders with almost no significant power in the process, not to mention running very rough.

Firing Order Frustrations

So during the original engine design by GM in the sixties the firing order was decided to be 1-8-4-3-6-5-7-2. This firing order is relatively common in V8's and creates a smooth running engine with cylinders "balanced" in their firing side to side. However with the "lost spark-siamesed" coil design, the spark needs to go to the cylinder pairs firing 180 degrees of rotation out of time. So those pairs are 1-6, 8-5,4-7, and 3-2. So unfortunately the pairs are on opposite sides of the engine. What this means of course is that to minimize the cost of spark plug wires by minimizing their length, the coils need to be centrally located.

Alternative Design Attempts

The above design analysis is typical of how I approach issues I have encountered over the years restoring and maintaining 20+ D2's with my inner engineer striving to come up with engineering solutions to these design shortcomings. Over the years I experimented with several alternative designs always striving to optimize the design. The ecu spark trigger lines don't seem to be able to support firing more than one coil, so that eliminated single coil on plug or even 4 siamesed coils (two per side). Other relocation kits exist of course but their location requires custom spark plug wire sets at an exorbitant cost ($300 ish) and comes with the downside that spare spark plug wires are not cheaply and readily available.

Alternative siamesed coils with different shapes were a possibility however none existed that accepted the spark plug wire ends used on the Thor style coils, meaning at a minimum an all new spark plug wire set would be needed and potentially custom wires due to length.

Design Optimization

Ultimately the design of my kit is what you see here. I believe this design optimized the cost of the kit, long term operations cost (spares), maintenance convenience and access, and ease of installation.

Key advantages of the kit are:

- Utilizes factory spark plug wires, enabling owners to re-use existing wires and spares. The central location means that the factory spark plug wires for cylinder 7 and 8 are too short to be used, but any other factory wire can be used. The added benefit is that after buying a 2nd set of wires the owner now has spares available for usage.

- Relocates coils to underhood area with maximum cooling and heat rejection, likely extending the life of the coils. Unlike alternative relocation kits, the coils are not located near an exhaust manifold, cooling system hoses, or radiator fan airflow. Additionally, mounted to an aluminum mounting bracket (aluminum is a very efficient heat conductor) mounted to the aluminum upper intake manifold which has a constant ambient airflow running through it means that the coils are in effect being cooled by the intake airflow via conduction

- Enables 2 minute spark plug wire replacement and 5 minute coil replacement, without removal of any other components. Spark plug wire changes are now literally plug and play, with coil changes only requiring the removal of the mounting bolts.

- Minimal modifications to other underhood components - trimming of one hose and slight relocation of the Idle control valve.

- Minimal kit hardware, minimizing coil connect extension length and mounting bracket complexity and cost.

We hope you enjoyed this first in our series of future blog post regarding the design elements of the D2 and how Extinct Motorsports Engineering seeks to bring engineered solutions to the factory design issues that frustrate our enjoyment of an otherwise delightful driving experience.

If you would like to buy the kit follow this link and if you have any questions hit me up on twitter at Tweet to @ExtinctMtrsprts